Our LinkedIn & News

Vacancies - September 2024

• CNC MILLER / TURNER - HYDE, MANCHESTER

• QUALITY CONTROL INSPECTOR - HYDE, MANCHESTER

Would you like to join a growing engineering company with an excellent reputation and great working culture?

Have you worked within a precision engineering environment?

Coleherne Ltd is a privately owned engineering and manufacturing business. We specialise in the design, manufacture and repair of White Metal bearings and the supply of laser cut parts and laminations.

Vacancies now live. Click the link above to find out more.

Highlighted Posts & News >

Click on ‘See More Here’ on a LinkedIn post of interest and it will appear in a new window.

December 2025

EIC Connect – Reflections from Coleherne

At EIC Connect in Manchester last week, the theme Export – Diversify – Grow resonated strongly with where Coleherne is heading. For UK manufacturers supporting the power generation sector, it felt especially relevant.

Much of the discussion centred on issues we recognise across our own customer base: the need for sustained skills development, stable long-term policy, and a clearer pathway for getting approved energy projects into delivery.

November 2025

SEE John and Paul at EIC Connect - Thursday 20th November.

Coleherne Ltd will be at EIC Connect UK & Ireland Energy in Manchester this Thursday, and we’re looking forward to meeting organisations across the sector. As the energy landscape continues to evolve, our focus is on strengthening Coleherne’s role as a trusted engineering partner — supporting OEMs, operators and contractors with reliable bearing solutions and precision laser cutting services.

John Yeouart FInstSMM and Paul Salloway will be available throughout the day to discuss how Coleherne Ltd can support upcoming requirements and new partnerships.

Coleherne Joins EIC - Energy Industries Council (EIC)

We are delighted to announce our membership of the EIC. EIC is one of the world's largest energy trade associations for companies that supply goods and services to the energy industries worldwide. Coleherne provide expertis in fluid bearings and production of specialised laminations and far more. From new products to retrofitting and repair we are a perfect partner for the Energy Sector. Coleherne are the UK-based European agent for Kingsbury Inc, global leaders in fluid film bearing innovation.

Made in Greater Manchester. Sold to the World.

Today is a good moment to recognise the value of UK manufacturing on the global stage.

At Coleherne Ltd, our white metal bearings, laser cut parts, and engineered components travel far beyond Greater Manchester, supporting customers across the USA, EU and GCC.

Exciting News - John Yeouart, Coleherne Business Manager, at Hydro-Coleherne Oman in November

Once again, John will be visiting our Hydro Coleherne Oman facility from 2nd to 12th November. During this trip, he will be:

✅ Building on the fantastic progress from my last visit

✅ Introducing myself and Hydro Coleherne Oman to more of our Middle East network

✅ Exploring new ways we can support partners across the region

✅ Building on and promoting 'ICV - In Country Value'

Why not catch up over a coffee ☕ and chat about how we can collaborate.

📩 Feel free to message John to arrange a meeting — He’s always keen to connect with industry peers and explore new opportunities.

October 2025

Coleherne Are Hiring - CNC Vertical Boring Machine Tool Operator

We have several opportunities to join Coleherne Ltd in Hyde (Greater Manchester). Today we are highlighting the opening for a CNC Vertical Boring Machine Tool Operator. Enjoy benefits like a competitive salary, flexible hours, paid overtime, and a generous pension scheme. We provide a safe working environment with all necessary tools, PPE provided plus training and opportunities for personal development as our specialist white metal bearing business continues to grow.

Advancing Bearing Development Through International Collaboration

Advancing Bearing Development Through International Collaboration

Last week, Coleherne Ltd’s Paul Salloway visited Institut für Werkstoffanwendungen im Maschinenbau IWM der RWTH Aachen

(Institute for Materials Applications in Mechanical Engineering (IWM) at Aachen University) where met with their most excellent engineering researcher, Saliha Gündogan.

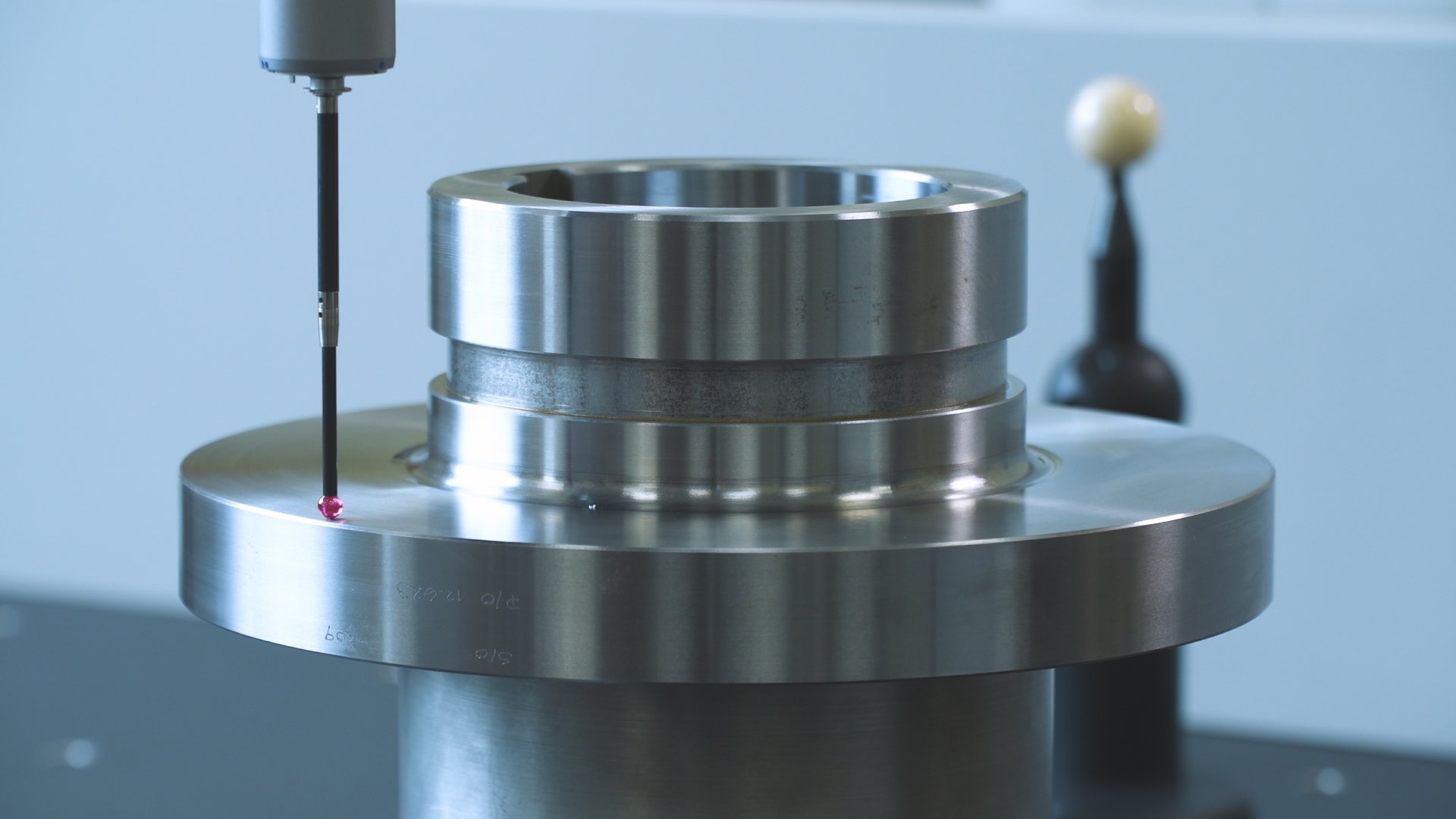

Quality In Everything We Do! - Watch the video…

At Coleherne Ltd, quality isn’t just a step in the process — it’s built into everything we do.

This short clip shows our Coordinate Measuring Machine (CMM) in action, carefully checking dimensions on a finished bearing.

September 2025

120 Years of Engineering Excellence - Celebrating Enduring Partnerships

This year we mark Coleherne Ltd’s 120 years of delivering trusted bearing solutions alongside 225 years of UK–Oman relations.

A productive day for Coleherne Ltd at the EIC (Energy Industries Council) Connect event in Muscat

Thank you to Ryan McPherson and the EIC team for organising an excellent programme, and to all the speakers for sharing valuable insight into future projects and investment in Oman – particularly in hydrogen and other renewable energy developments.

Continuing Growth in Oman

John Yeouart FInstSMM and Paul Salloway are in Muscat this week, representing Coleherne Ltd and Hydro Middle East LLC at EIC (Energy Industries Council)'s Connect event on Wednesday. Their visit marks part of a two-week programme, building on our established presence in Oman and strengthening valued relationships in the region.

August 2025

Relining and finishing of a large diameter steady bearing

Coleherne Ltd has just completed the re-lining and finish machining of a large white metal steady bearing – 18" diameter by 22.5" long – for a hydro power station in Scotland.

Jobs like this really show the scale and precision involved in our work.

May 2025

Dr Gary Dyson’s Keynote Speech On Hydro Incs Approach To Sustainability

A key moment for Coleherne Ltd and Hydro Middle East LLC at the Oman Petroleum & Energy Show was Dr. Gary Dyson’s technical presentation on Hydro, Inc.’s approach to driving sustainability through engineered pump efficiency.

By optimising hydraulic performance, reducing energy consumption, and extending component life, Hydro LLC is contributing to Oman’s emissions reduction targets — one pump system at a time.

Team Coleherne at OPES 2025!

Jeremy Taylor, John Yeouart FInstSMM and Paul Salloway are exhibiting with Coleherne Ltd and Hydro Middle East LLC at the Oman Petroleum & Energy Show (OPES) 2025.

📍 Stand 4250

📅 May 12–14

📌 Oman Convention & Exhibition Centre, Muscat

Come and talk to us about how Hydro Coleherne combines UK engineering expertise with local manufacturing and repair in Samail, Oman — delivering trusted bearing solutions for the region’s energy sector.

For lots more interesting content including videos see our LinkedIn feed.

See more here.

Hydro Coleherne at OPES 2025 – See You in Oman!

We’re exhibiting at the Oman Petroleum & Energy Show (OPES) 2025 with Hydro Middle East LLC.

📍 Stand 4250

📅 May 12–14

📌 Oman Convention & Exhibition Centre, Muscat

Discover how Hydro Coleherne combines UK engineering expertise with local manufacturing and repair in Samail, Oman — delivering trusted bearing solutions for the region’s energy sector.

April 2025

Compressor Gearbox Journal Bearing Repair

Another high-quality repair completed by the Coleherne Ltd team in Oman for a local oil and gas company. Downtime from worn white metal bearings in vapour compressors can be costly, but our UK and Oman engineering teams deliver fast, dependable solutions.

Coleherne Welcomes Sarah Worrall as Laminations Division Production Manager

Coleherne Ltd has always been proud of our skilled and hard-working women, so we are very happy to introduce our new Production Manager in our Laminations Division: Sarah Worrall.

Sarah began her career in 1994 at Ryecroft Engineering, gaining extensive production experience before joining Coleherne at its founding in 2017.

Frame 9E Gas Turbine Tilting Pad Journal Bearings

Another quality repair carried out by the Coleherne Ltd team in Oman. Downtime due to faulty Frame 9 white metal bearings can be costly. Whether you need design, re-engineering, manufacturing, or repair, our UK and Oman engineering teams provide rapid, reliable solutions.

March 2025

Coleherne and J Taylor Holdings – Help To Grow

Coleherne Ltd recently engaged with Manchester Metropolitan University Business School's Help to Grow: Management programme, an executive course designed to help British small businesses scale and strengthen its leadership. Delivered by experts from the university’s triple-accredited Business School, the programme offered practical strategies for growth and resilience.

The key takeaways for the members of our management team that attended the 12 modules over the last 4 months…

Coleherne Continues To Grow

Coleherne Ltd continues to grow at our Hyde works in Greater Manchester in order to better support our customers in the power and energy sectors.

We have recently connected with a recently vacated workshop that is adjacent to our main white metal bearing manufacturing workshop.

February 2025

CPD in London

As part of my Continuous Professional Development (CPD) with Coleherne Ltd, last week I went to London for UK Research and Innovation Materials and Manufacturing Showcase for my dose of CPD. With around 1,000 delegates this event was buzzing. Interesting to gain insight how UKTI can help support business growth and a great chance to hear from the leading experts in materials science.

What a Busy Couple of Weeks!

As an engineer based in the UK, I have seen first-hand how Brexit and a non-existent industrial strategy have both failed to create skilled jobs, strengthen communities or drive innovation. At the end of last year, the new UK Government outlined key sectors to focus-on for long-term growth and reverse those past failures. How this is implemented will shape who truly benefits?

Trade Tariff Uncertainty and a UK-EU Reset are here: What about the UK’s Industrial Strategy?

As an engineer based in the UK, I have seen first-hand how Brexit and a non-existent industrial strategy have both failed to create skilled jobs, strengthen communities or drive innovation. At the end of last year, the new UK Government outlined key sectors to focus-on for long-term growth and reverse those past failures. How this is implemented will shape who truly benefits.

January 2025

William Shakespeare and Bearing Innovation

Amongst many other things – mostly working my way through my ‘to do’ list for our new Business Manager – last month I went to Stratford-Upon-Avon. This is the birthplace of William Shakespeare, the most famous poet and playwright in the English language. Usually rammed with tourists, on a gloomy December afternoon, it was remarkably quiet. Anyway, Coleherne Ltd have a few interesting innovations in the pipeline – teaser for later in 2025

Happy New Year to All!

My wife and I are having a few weeks of downtime in Oman.

Thank you to the Crowne Plaza Sohar for looking after us there after the New Year busy period had subsided. The reception team made an excellent recommendation for the Sohar festival. Total immersion, Oman style - cultural, heritage and culinary delights.

December 2024

Coleherne recruits New Business Manager.

Coleherne Ltd has a new Business Manager, John Yeouart FInstSMM. He has extensive experience developing and managing businesses within the Oil & Gas, Marine and Renewable Energy sectors so it was good to work with him 1-on-1 for a couple of days last week.

We reviewed our existing marketing materials and explored in detail some of the new products and services that we intend to bring to market in 2025.

Getting Government working with Greater Manchester hosted at the MMU.

Last Thursday evening I was invited to an event promoting an initiative to get government working with Greater Manchester to support our local SMEs to export. This event was standing room only – I heard that instead of 20% no-shows for this type of thing, 20% more people turned up. Perhaps because our local MP, Business and Trade Secretary (Jonathan Reynolds MP), and Mayor of Greater Manchester, Andy Burnham, were both speaking

21 employers invited to MMU Campus, recruiting for over 30 live vacancies.

Thank you to Avina Cheenibass and team for such a memorable event. It was a great event MMU.

Also, my thanks to all the young engineers who took the time to prepare themselves for the day and then subject themselves to some tough interview questions.

November 2024

Back in the lab at MMU!

Diversification and Innovation

Greater Manchester Electrochemical Hydrogen Cluster (GMEHC) aims to speed up the development and adoption of electrochemical hydrogen technology in businesses across Greater Manchester. They offer local businesses bite-sized innovation workshops to explore and understand the potential of hydrogen as a fuel source for their business.

See more here.

Driving New Products and Services at the Innovation Retreat. Organised by The Growth Company

Greater Manchester - Driving New Products & Services

The Innovation Retreat, organized by The Growth Company and funded by the Shared Prosperity Fund (SPF), is designed to help SMEs across Greater Manchester create actionable plans for prototyping and launching new products and services. Each cohort of 15 business or project leaders learns a lean, repeatable innovation process from the experienced team at the Manchester Metropolitan University Business School (MMU). This approach can be applied across the initiative's target sectors: advanced materials, AI, and biomedical.

Last week, the cohort gathered in Wigan for the intensive 2-day residential phase.

Back to the MMU!

This trip to the Manchester Metropolitan University Business School was engaging in many ways.

At the Business School, the focus was on clarifying problem statements and refining value propositions with Dr. Kadja Manninen. These steps are essential in understanding the practical challenges engineering firms face in developing business plans.

October 2024

Coleherne Ltd is proud to support grassroots sports by sponsoring the Cheetham Hill Junior Football Club Under-10s team!

Our finance director, David Morrison, takes on a dual role as both coach and manager, demonstrating his passion for the sport beyond the office.

Even though our workshop seems to be divided between Manchester City Football Club and Manchester United fans, we are all united in backing this city’s next generation of young footballers.

At Coleherne, we believe in fostering talent, teamwork, and community spirit, values that resonate both on and off the football pitch.

September 2024

White Metal Bearing Beyond Economic Repair? – Think Again (Part 2)

You may recall this collection of pinion shaft bearings in the ‘scrapyard’ (the customer’s term, not ours) and the great job we did repairing one of these 320mm diameter pinion shaft bearings?

The Coleherne Ltd white metal bearing repair team, based at the Hydro Middle East LLC facility in Oman, reverse engineered then refurbished one of these complex bearings on an urgent basis for a cement works in the region.

We are pleased to introduce two young engineers at Coleherne Ltd.

Louis Ratcliffe a Technical Sales Engineer. He has been with our Laser Division since 2018 after completing a BTEC in Mechanical & Electrical Engineering. Louis has experience across the laser production process and now works in technical sales, customer relations, purchasing, and CAD-CAM.

Luke Taylor a Production Engineer in our Bearings Division. He first joined Coleherne in 2017 and returned in 2024 after completing a Business Management and Marketing degree at Leeds University. Luke now supports our workshop manager with production planning in the white metal bearing division.

The laser division at Coleherne Ltd are really pleased to have been helpful in getting SoilSafe Ltd some critical parts for their forklift.

This was an urgent request for laser cutting with a premium next-day turnaround. Our services included laser cutting, drilling, and milling. We met the delivery targets, ensuring the customer received their prototype in time for the exhibition.

Always happy to help a local company to succeed. 👍

August 2024

White Metal Bearing Beyond Economic Repair? – Think Again (Part 1)

Looking at this collection of pinion shaft bearings in the ‘scrapyard’ (the customer’s term, not ours), you would think they were indeed scrap.

The Coleherne Ltd white metal bearing repair team, based at the Hydro Middle East LLC facility in Oman, reverse engineered then refurbished this complex bearing for a cement works in the region.

Showcasing Custom Laser Cut Parts for Landscaping, Architecture, and Structural Projects

We recently had the pleasure of collaborating with a local fabricator to bring their unique vision to life.

Tasked with designing a bespoke set of steel gates that truly stand out, our Laser Division in Hyde delivered results that exceeded expectations—combining strength, functionality, and aesthetics.

July 2024

Pump Bearing Repair – Qatar

Here is a 5” diameter Dodge combined journal and thrust bearing that the Coleherne Ltd bearing repair team recently refurbished at the Hydro Middle East LLC maintenance facility in Oman for an OEM pump service company based in Qatar.

White Metal Bearing Training

Our technical support engineer, Paul Salloway, delivered a great seminar of white metal bearing technology on behalf of Hydro, Inc. and Hydro Middle East LLC last Wednesday.

If you would like to know more about our offering for face to face training in the UK, EU or USA then please look here: https://lnkd.in/eAkmSVcC or for our online training here: https://lnkd.in/gkt8Grzg

Free Webinar ‘White Metal (Babbitt) Bearings’ on 3rd July

White Metal bearings form a critical part of your rotating plant and machinery. The consequences of “getting it wrong” are significant. Coleherne Ltd offers specialist training courses for engineers, technicians, mechanical engineering fitters and operational maintenance staff.

June 2024

Tilting Pad Journal Bearing Repairs In Oman

Another top-class bearing repair project from the Hydro Coleherne team in Oman.

Based at the Hydro Middle East LLC's plant in Samail, our Coleherne Ltd engineers have just completed a full refurbishment of this 290mm diameter tilting pad journal bearing and a 260mm diameter combined tilting pad journal and tilting thrust pad bearing.

Coleherne Ltd ISO-9001 Certificate of Registration

We are making our latest ISO 9001 Quality Management System Certificate of Registration from BSI available to our partners across the energy, power generation and industrial markets both at home and abroad.

This achievement underscores our unwavering commitment to quality and customer service in every aspect of our business.

April 2024

White Metal Bearing Training At South Humber Bank Power Station

During a recent overhaul, the engineering team at the EPUKI South Humber Bank Power Station recognised the need for some training for their technicians in white metal bearings.

March 2024

White Metal Bearing Training At Stanlow Oil Refinery

Coleherne Ltd has just completed our third of our series of two-day training course on the theory and practical fitting of white metal bearings

September 2023

Tameside Means Business!

The #Tameside Means Business team enjoyed a captivating visit at the ground-breaking Hyde-based engineering global company Coleherne Ltd alongside sales engineer Stephen Carrington-Ward.

Coleherne, who have a facility in Oman, draws on over 100 years of engineering expertise to provide a complete refurbishment and remanufacturing service for white metal bearings, and they supply bearings to all the major global rotating plant equipment manufacturers from the UK.

Dan, James & John proudly showing their medals for an amazing achievement.

July 2023

The Christie Manchester to Blackpool Bike Ride

Dan, James and John from the bearing repair section at Coleherne Ltd successfully completed The Christie Charity Manchester to Blackpool bike 2023. 60 miles of pedalling in blazing sunshine and pouring rain – a typical summers day in England. Why not visit our Just Giving page in the story and donate to this worthy cause?

May 2023

25.5” dia x 34” Motor Bearing Manufacture - Legacy bearing replacement

Coleherne Ltd recently completed the manufacturing of a very large ring lubricated white metal bearing for an export order from a major UK original equipment manufacturer.

White Metal Bearing Training With Essar’s Mechanical Engineering Maintenance Technicians at Stanlow Oil Refinery

Coleherne Ltd have just completed a wide-ranging and in-depth two-day training course on the theory and practical fitting of white metal bearings for a group of mechanical engineering maintenance technicians at Essar Oil (UK) Limited's Stanlow refinery. This course is the 1st of a series of 3 schedules courses this summer to prepare Essar’s engineering team for an upcoming maintenance period later in the year.

April 2023

Hydro - Coleherne Middle East respond to emergency gearbox repair over a weekend

Great to see the #oman based team from Coleherne Ltd and Hydro Middle East reacting in such a positive way to support this customer's critical repair over this weekend. We look forward to making them some spare bearings in the next few months.

Manufacturing of Complex White Metal Parts

We recently manufactured a Hydrogen Seal at our Hyde works in Manchester for a major European power station.

Please contact our UK and Middle East teams for further details.

January 2023

We are pleased to confirm that Coleherne’s JV With Hydro in Oman is now fully operational.

Hydro Coleherne LLC can now service (Repair and New) all types of White Metal Bearings from our facility in Samail (near Muscat) – Supporting clients across the Middle East and North Africa

Our presentation you can see here gives some detail on our services.

Face-to-Face Bearing Training For Engineers - Dec 2022

We have had a great end to 2022 with a training course recently conducted with our partners Hydro, Inc. in the USA.

NEW Oman Website

You can visit this here www.hydro-coleherne.com

White Metal Bearings highlight

• White Metal Gearbox Bearing Failure LinkedIn discussion - October 2022

LinkedIn is a great online forum for discussing and learning about white metal bearing failures.

NEW : Training across the GCC (The Arab States of the Gulf)

NEW • We are now able to offer Hands-On White Metal Bearing Training expertise across the GCC

MD Jeremy Taylor’s Visit to London - January 2022

Renewable Energy Projects

Laser Cutting

Training Course at Sizewell B

• Course instructed by Coleherne’s Paul Salloway at EDF's Sizewell B Technical Training Centre